The Advanced Medical Technologies Program provides medical additive manufacturing (3D printing) and virtual surgical planning services to clinicians, educators and researchers within Penn State Health and College of Medicine for:

- Case-related clinical needs

- Medical research

- Medical education/teaching

For all other 3D printing services, please contact the Harrell Health Sciences Library.

Click here to order a 3D printed model

If you are not sure what you need, contact Advanced Medical Technologies for assistance.

For clinical cases: Please provide the relevant patient details when filling out the form. CMI and Radiology will cover the cost of the print. The patient’s case and the requesting clinician will receive a zero-cost invoice showing the total value provided.

If you have a funding source: Please indicate your funding source (e.g. you have a grant that will cover the cost of printing). Direct costs will be charged to your funding source.

If you do not have a funding source: Please indicate on the order form if you do not have a funding source to pay for your requested job. We will evaluate your request to determine if it will be covered.

Jump to topic

Search

Learn More About Advanced Medical Technologies

Advances in medical technologies have transformed the practice of medicine. As a leading research institution in engineering and materials science, Penn State has been at the forefront of that transformation with projects such as the artificial heart. Today, technology continues to revolutionize medicine and at an ever-faster rate.

The Advanced Medical Technologies Program is dedicated to the identification, development and integration of cutting-edge technologies into clinical practice, medical education and research. The program provides advanced tools directly to clinicians, educators and researchers within Penn State.

The overall goal of the Advanced Medical Technologies program is to promote collaborations between Penn State’s academic medical center and its engineering research institutions with the purpose of enhancing health. It accomplishes this by helping clinicians, engineers and educators drive breakthroughs in improving the standard of care, achieving better patient outcomes and enhancing Penn State’s ability to educate the next generation of clinicians and biomedical researchers.

The Advanced Medical Technologies program provides medical additive manufacturing services and will add other capabilities in the future. Services are offered in collaboration with the following resources and departments:

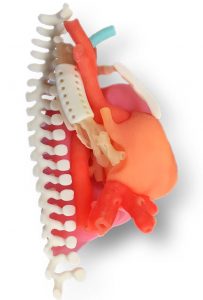

Medical additive manufacturing and 3D imaging for:

Surgical Planning

- Preoperative planning

- Virtual surgical planning

Education

- Anatomical training

- Surgical and procedure simulation

- Patient and care team education

Basic Research

- Construction of physical 3D models to enable the study of structure-function relationships

Medical Device Development and Testing

- Rapid functional device prototyping

Future Services in the Pipeline

- Surgical planning (surgical guides – drill and cut guides)

- Rehabilitation (patient-specific braces and devices to orient body and provide a stable recovery platform)

- Custom prosthetics

Read more about Advanced Medical Technologies’ 3D heart model printing program for patients with congenital heart disease in this Penn State Health News article.

The Advanced Medical Technologies Program offers two different printing technologies, stereolithography and fused deposition modeling. Both have advantages and disadvantages, and the program helps investigators decide what is best for a particular use.

The program can also provide prints that employ other printing technologies to produce metal parts as well as models with multiple colors and material densities. Contact the program for details.

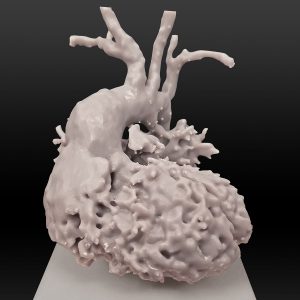

This is a gray stereolithography 3D-printed heart model from a Formlabs printer.

Stereolithography

Stereolithography is an additive manufacturing process that works by focusing an ultraviolet laser on to a vat of photopolymer resin. This triggers photopolymerization, a process by which light causes chains of molecules to link and forms polymers or materials made of long, repeating chains of molecules. Those polymers form the body of a 3D solid, such as an anatomical model or prototype.

Stereolithographic medical models can create accurate 3D models of various anatomical regions of a patient based on data from a computerized tomography (CT) scan or magnetic resonance imaging (MRI). This data consists of a series of cross-sectional images of the human anatomy created by Penn State Health’s 3D Imaging Lab. Stereolithographic models are used for patient or student education, preoperative planning and patient-specific surgical guides.

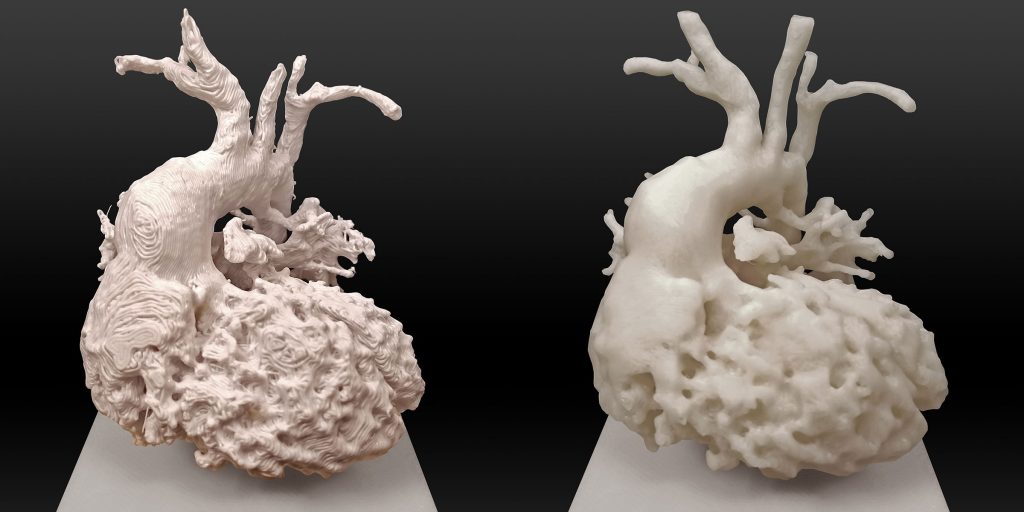

Fused Deposition Modeling

Fused deposition modeling is an additive manufacturing process that creates a 3D model by laying down material in layers.

This process can be fast and inexpensive when compared with stereolithographic 3D printing, building accurate 3D models of various anatomical regions of a patient based on data from a CT scan or MRI. Fused deposition modeling prints can be used for patient or student education and preoperative planning. The Advanced Medical Technologies Program offers both inexpensive, low-resolution and more expensive, high-resolution fused deposition modeling capabilities.

On the left is a lower-resolution, more inexpensive fused deposition modeling print from a Lulzbot printer, and on the right is a more expensive, higher-resolution fused deposition modeling print from a Fortus printer. The Advanced Medical Technologies Program offers both options.

The following cases demonstrate how the Advanced Medical Technologies program is being utilized for real-world scenarios impacting clinical care, education and research.

Pacemaker Lead Placement via Transmural Approach in an Adult With Palliated Single Ventricle Heart Disease

This case demonstrates the utility of 3D printed models to aid in the placement of medical devices in patients with complex anatomy. While a prior study demonstrated the possible use of permanent transvenous pacemaker leads in certain types of Fontan patients, placement of an endocardial pacing lead directly into the atrium in a Fontan patient via a transmural approach has only been rarely described previously, with the approach most typically utilized at the time of concomitant heart surgery. The ability of preoperative 3D printing makes such an approach feasible when other heart surgery is not required.

Phone: 717-531-8990

The Advanced Medical Technologies Program is dedicated to the identification, development and integration of cutting-edge technologies into clinical practice, medical education and research. The program provides advanced tools directly to clinicians, educators and researchers within Penn State.

The Advanced Medical Technologies Program is dedicated to the identification, development and integration of cutting-edge technologies into clinical practice, medical education and research. The program provides advanced tools directly to clinicians, educators and researchers within Penn State.